All Blogs

𝔰𝔯𝔠 INOMETA

𝔰𝔯𝔠 INOMETAElectric Heating Roller, Not Just For The Lamination Process

What are heating rollers used for? Why do you need heating rollers and what are they? A heating roller is a cylinder or roller that can be kept at a constant...

Double Adhesive Tapes for Flexo Printing

What is the function of the adhesive layer? In flexo printing, the cross section up of double adhesive mounting tapes generally consists of adhesive on both...

𝔰𝔯𝔠 IMC

𝔰𝔯𝔠 IMCMounting Tapes for Flexo Printing

What is the general purpose of mounting tapes for flexo printing? Well - it needs to stick! Flexographic printing requires mounting tapes to fixate the...

𝔰𝔯𝔠 Solomon203

𝔰𝔯𝔠 Solomon203Tips for Flexo Corrugated Printing

Choosing a printing method for corrugated packaging involves evaluating factors such as production speed, print quality, flexibility, cost, and required...

𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFAColour Proofing in Flexo Printing

Flexo colour proofing stage, a crucial phase in the pre-press process, offers customers a visual preview of their final printed piece, guiding contractual...

𝔰𝔯𝔠 INOMETA

𝔰𝔯𝔠 INOMETAWinding Cores in Foil Processing: Aluminium vs. Cardboard Tubes

What does the choice of an optimal winding core contribute to the result of a print job? First of All Winding cores are used to wind or unwind foils, papers...

Flexo Printing in the Lens of ESG

In an era where sustainability and corporate responsibility have taken centre stage, Environmental, Social, and Governance (ESG) criteria have become a...

Unlock the Secret to Better Printing: Key to Ink Surface Tension and Bonding Revealed

If you work in the flexographic printing industry, you know better than anyone that there are hundreds of moving parts to align, test, and measure to get the...

𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFAThe Science of Flawless Printing: Understanding Flexo Surface Tension, Surface Energy, and wettability

Achieving good adhesion and print quality is essential for any printing job. This starts with ensuring that the ink wets out on the substrate fully and...

Maximise Your Printing Potential: A Guide to choosing the right flexo printing machine

Buying a flexo printing machine is similar to buying a car. You want to strike the right balance between safety, functionality, and quality without blowing...

𝔰𝔯𝔠 RawPixel

𝔰𝔯𝔠 RawPixelUnlocking the Potential of Sustainable Printing: Flexo vs. Screen, Gravure, Litho, and Offset

As the manufacturing industry moves toward more environmentally friendly practices, it's critical to consider whether you're using sustainable printing...

𝔰𝔯𝔠 Arthur Rothstein

𝔰𝔯𝔠 Arthur RothsteinFlexo vs Digital Printing – Which is the Better Choice?

In the ever-evolving landscape of the printing industry, the debate between traditional and innovative techniques remains a poignant subject for industry...

The Ultimate Showdown: Comparing Litho, Screen, Digital and Flexo Printing for Corrugated

For shipping, a variety of consumer products are packed into corrugated containers. Many businesses ship products in shelf-ready packaging to save money. The...

[Flexo Flaw Fixing] Gear Marks

This article is part of the FLEXO FLAW FIXING series Identification of gear marks in flexographic printing is an uncomplicated task, as they manifest as...

Flexo and Offset Printing: Battle of the Titans

Packaging printing offers diverse methods, like flexo, digital, gravure, and offset printing. When dealing with top-tier quality, consistent, long-run jobs,...

𝔰𝔯𝔠 Brett Jordan

𝔰𝔯𝔠 Brett JordanAchieving Compliance for Blister Packs with Flexo Printing

In the highly regulated pharmaceutical industry, exceeding stringent standards is critical. It's not just an advantage, it's a requirement for product safety....

𝔰𝔯𝔠 Bearfotos

𝔰𝔯𝔠 BearfotosPicture Perfect Solutions: Optimise Your Imaging Equipment with Professional Image Carrier Technical Support Services

Because flexographic printing is a niche segment of the printing industry, locating technical support when a printing defect occurs can be difficult. Should...

Overcoming foil embossing obstacles: A guide to identify and fix common challenges and defects

As more products enter the market, marketing departments devote more resources to product branding. Branding experts have challenged the way products are...

𝔰𝔯𝔠 AGFA

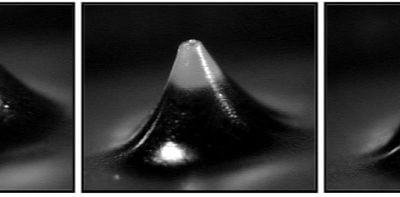

𝔰𝔯𝔠 AGFAMaximising the Potential of Flat Top Dots: A Guide to communicating with your Image Carrier Manufacturer

Paying attention to the smallest details can make a big difference in the world of flexographic printing. Flat top dots profiles are one minor detail that...

Diagnosing and Resolving Flexo Printing Defects: A Comprehensive Troubleshooting Chart

There is a formula for printing success. There isn't enough press downtime while troubleshooting defects. Time wasted is money lost. This diagnostic...

𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFAAchieving Optimal Print Quality on Flexible Packaging: Expert Tips and Techniques

It's no secret that one of the most common and popular types of product containers is flexible packaging. A "flexible package" refers to any type of packaging...

Flexography vs. Lithography in Narrow Web Printing

In the versatile sector of narrow web printing, particularly for labels and packaging, two primary printing technologies stand out: flexo printing (also known...

𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFAThe Ultimate Anilox Volume Reference (+Our Free Printable Chart)

During Flexographic Printing, anilox volume refers to the carrying capacity of an anilox cell or the amount of ink held in each cell. It is one of many...

Exploring the Superior Benefits of Elastomer Blends Compared to Photopolymers

It's no secret that large-scale printing operations have long been popular. But would it surprise you to learn that tire companies have long supplied...

𝔰𝔯𝔠 Brett Jordan

𝔰𝔯𝔠 Brett JordanExpert Solutions for Resolving Blister Packaging Printing Issues in Flexo Printing

Flexographic printing on blister packaging can achieve high-resolution printing results, but care must be taken not to damage the seal's integrity so that the...

𝔰𝔯𝔠 Brett Jordan

𝔰𝔯𝔠 Brett JordanCurrent Pharmaceutical Packaging Trends in Flexo Printing

Pharmaceutical packaging is a $124 billion global market that is growing at a CAGR of about 6% year over year. In contrast to other packaging segments,...

Flexo Printing vs Screen Printing: What’s the difference?

In the world of printing, there are numerous techniques available, each offering its own advantages and limitations. Two commonly used methods are flexo...

Drying in Flexo Platemaking

This blog was written and submitted to us by Torben Wendland The drying step in flexo platemaking of photopolymer plates is only necessary for solvent...

Troubleshooting Flexo Printing on Film Substrates

In the flexo printing industry, the choice of substrate plays a key role in determining the quality and efficiency of the final product. Film substrates reign...

𝔰𝔯𝔠 Solomon203

𝔰𝔯𝔠 Solomon203The Application of Flexo Printing in Corrugated Packaging

Advancements in corrugated package printing have brought about remarkable transformations in the packaging industry. Traditionally, corrugated packing...

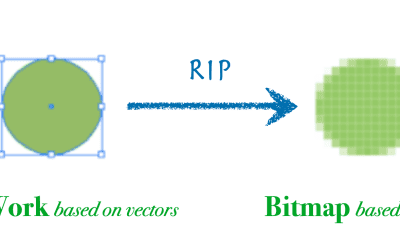

RIP and Software Solutions in Flexo Printing – Part 2

As we enter the digital age, the printing industry has undergone a remarkable transformation. The era of cumbersome traditional processes is over. Advanced...

RIP and Software Solutions in Flexo Printing – Part 1

Printing has evolved into a complex interplay of technology and craftsmanship, with the Raster Image Processor (RIP) sitting at the heart of this...

FlexoPrint Mobile Application

FlexoPrint is a special, useful and free mobile application. Excellent for prepress personnel responsible for photopolymer plate processing, print quality and...

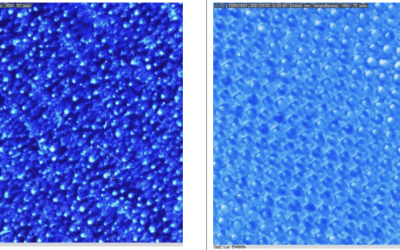

FingerPrint and Proofing Flexography

What is Flexo print colour management? Flexo print colour management manages every step in context, matching the COLOURS of Contract Proof and Print-Run. And...

𝔰𝔯𝔠 ECTran71

𝔰𝔯𝔠 ECTran71Anilox Rollers in Flexo Printing

What Constitutes an Anilox Roller in Flexo? An anilox roller, a critical component in flexographic printing, consists of a steel or aluminium core enveloped...

Flexo Chronicles: An Anthology of Flexo Printing history (Part 2 of 2)

Since its invention some 130 years ago, flexography has come a long way. This two-part series covers the origins of Flexo printing as well as its growth in...

Flexo Chronicles: An Anthology of Flexo Printing History (Part 1 of 2)

Over the last two decades, flexographic printing has grown in popularity, with roughly 60% of the entire packaging industry utilizing flexography in the...

Flexographic Image Carrier Production: A Look behind the Scenes

If you've ever wondered how the flexographic printing process works, image carrier services are an important component. Flexographic printing plates or...

How often should you calibrate your Anilox Rollers

Flexo printing and coating is a liquid application process. This process requires precise control of the amount of ink applied to the substrate so that the...

Sustainable Packaging Trends

What is sustainable packaging? The term "sustainable packaging" refers to packaging that does not produce pollution, harm the environment or harm human...

How Does Sustainable Packaging Help Environment

Sustainable manufacturing processes are essential to creating packaging that can be recycled, reused, and re-used. After many years of doing this, we've...

What You Should Know About Flexo End Seals

Choose the correct flexo end seals for your application to achieve proper doctor blade seating. If used correctly, these low-cost consumables can save...

[Flexo Flaw Fixing] Ink Spitting

This article is part of the FLEXO FLAW FIXING series In the delicate art of flexo printing, each component of the press plays a crucial role in working in...

𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFADismantling an In-Line Printing Press

Different styles and types of printing presses exist to serve the diverse flexographic printing industry, with a wide range of substrate materials and sizes,...

Flexo Printing: 4 Sustainable Packaging Inks

Flexo printers frequently wake up in a cold sweat from inky nightmares. Maybe that's an exaggeration, but ink-related issues can keep flexo printers awake at...

𝔰𝔯𝔠 PxHere

𝔰𝔯𝔠 PxHereFlexo 101: The 5 Primary Types of Printing Presses

The printing industry features several different operational methods and types of printing presses. There are eight main types of presses in use, each with...

𝔰𝔯𝔠 Roy Shearer

𝔰𝔯𝔠 Roy Shearer4 Ways Laser Engraving Improves Flexo Print Quality and Efficiency

You're probably aware of how flexo printing has evolved in response to economic and demand pressures. As industries produced more, they necessitated more...

Flexo Print Sleeves, Cylinders, and Plates Care and Maintenance

The importance of adequate care and maintenance methods cannot be overstated when it comes to maximizing the lifespan and usability of flexographic printing...

Best Reasons to choose Narrow or Wide Web Flexo Printing

When printing on the web, large rolls of material are fed through a press at a high volume. The web presses usually operate much more quickly than the...

𝔰𝔯𝔠 Pixabay

𝔰𝔯𝔠 PixabayVarnish Coating in Flexo printing

What is varnish coating in flexo printing? The process of varnish coating in flexo printing involves applying a transparent layer of silicon over a printed...

Surface Tension Test Ink Makes Wettability Measurable

One of two critical components in optimized substrate wetting is surface tension (the other being surface energy). Tension is what enables moving liquids to...

What is a turn bar on web press?

The Turn Bar on a web press allows you to easily flip over prints. Printing on both sides of the paper is possible with this device. The Turn Bar makes it...

𝔰𝔯𝔠 Pixabay

𝔰𝔯𝔠 PixabayDrying Methods of the printing inks in flexography

Printing with flexographic technology involves directly applying ink to a printing plate, which is then transferred to the substrate. The printing plate is...

Choosing the Right Flexo Doctor Blades for Your Business

In the dynamic world of flexographic printing, achieving high-quality prints with maximal efficiency hinges significantly on the choice of components used in...

Flexo Printing Plate Makers and File Formats

Flexographic plates play a crucial role in achieving top-notch prints for advertisements, packaging, and labels. To begin using a flexographic printer, the...

The Application of Flexible Packaging

Flexible packaging represents a dynamic evolution in packaging solutions where functionality meets adaptability. Unlike conventional forms of packaging,...

How does my Anilox Roller Affect My Print

The Role of Anilox Roller in your Print What is an Anilox Roller? An anilox roller is one of the most important components of the flexographic printing...

Flexo Plate Making Process

Making flexo printing plates is indispensable in the production of packaging materials and labels, demanding a rigorous production process. By leveraging...

How to print self adhesive labels

Self-Adhesive labels: In flexo printing, self-adhesive labels are available in two types: heat-sensitive and pressure-sensitive. Heat-sensitive: A certain...

𝔰𝔯𝔠 Marco Verch

𝔰𝔯𝔠 Marco VerchImportance of Temperature and Humidity in your Print Room

Why Are Temperature and Humidity Factors Should Be Monitored in Printing Process? Temperature and humidity are the two environmental factors that are...

The Problem of Scoring Lines on Anilox Rolls

What Are Scoring Lines on Anilox Rolls? Scoring lines is one of the most problematic and costly defects of anilox rolls in flexographic printing. It should be...

Ways to Enhance Anilox Rolls Life

What Is the Average Life of Anilox Rolls? Anilox rolls are undeniably the most important component of the flexographic printing press. However, they are very...

Viscosity & pH: Key Factors for Optimal Flexo Ink Performance

Introduction When it comes to flexographic printing, the characteristics of the ink are paramount for achieving high-quality prints and maximising the speed...

Foiling in Flexography

Foiling is the process of adding a foil layer over printed images to increase durability, contrast, and glossy finish. It is commonly used on images that will...

Flatbed Die Cut in Flexography Advantages

Among the dies used in flexography, flatbed die cuts are some of the most popular. It gives a professional appearance and is easy to use. Due to its...

𝔰𝔯𝔠 Pixabay

𝔰𝔯𝔠 PixabayVarnishing in Flexography

Varnishing in flexography is a finishing process that is typically used on paper products such as prints and posters to give them a smooth finish. Two steps...

Laminating Process in Flexography

The product is laminated in flexography using two different processes. The first is manual, and the second is automatic. Heat press, adhesive, and lamination...

Rotary Die Cut Advantages and Disadvantages

In flexography printing, die cutting plays an important role. With die cutting, the print job is faster and requires less hands-on effort, which can be...

Elastomer vs. Photopolymer in Flexo Image Carriers

When it comes to the production of flexographic image carriers, two primary materials stand out: elastomers and photopolymers. How do these materials differ...

Corona Treatment in Flexo Printing

In the competitive market of flexographic printing, high-quality print and packaging production hinge on the fine balance between innovation, precision, and...

Quality Control Guide in Flexo Printing

Flexo printing demands high levels of printing quality. Quality control in flexographic printing is paramount to ensure that the final product meets or...

Press Operator in Flexo Printing

Flexo printing technology, considered the future of printing, offers a wide range of features and benefits to meet a variety of customer needs. The technology...

Narrow Web Flexo Printing

Application of Narrow Web Flexo Printing Narrow web flexo printing, a dynamic subset of flexographic printing, shines as a highly adaptable and efficient...

Flexo Printing Process Explained Step by Step

Flexo printing is a widely used printing process for producing high-quality prints. While it may seem simple, precise adherence to specific steps is crucial...

Exploring the Diversity of Flexo Inks for Optimal Printing Solutions

In the world of flexographic printing, the pivotal role of ink cannot be underestimated. Ink stands at the heart of the flexographic printing process,...

How to design for Flexo Printing?

The process of flexo printing is very different from that of offset printing. There are many similar issues to screen printing, but they are much more...

Flexo vs Gravure Printing: A Comprehensive Comparison

When it comes to modern commercial printing techniques, Flexographic printing and Gravure printing (also known as Rotogravure) are at the forefront. However,...

Washout Processing in Flexo Platemaking

This blog was written and submitted to us by Torben Wendland During photopolymer washout processing in flexo platemaking, the final plate relief is...

[Flexo Flaw Fixing] Skip-Out Effect

This article is part of the FLEXO FLAW FIXING series In the precision world of flexo printing, skip-out effect is like an unwelcome ghost haunting the presses...

![[Flexo Flaw Fixing] Doughnut Effect](https://flexopedia.net/wp-content/uploads/2022/07/067_Doughnut_Effect-1-e1704214721857-400x250.webp) 𝔰𝔯𝔠 Rachel Sandquist

𝔰𝔯𝔠 Rachel Sandquist[Flexo Flaw Fixing] Doughnut Effect

This article is part of the FLEXO FLAW FIXING series What Is Doughnuts Effect in Flexo Printing? The doughnut effect in flexo printing, also known as hollow...

[Flexo Flaw Fixing] Feathering

This article is part of the FLEXO FLAW FIXING series In the realm of flexo printing, feathering is a conspicuous enemy, marring an otherwise pristine print...

![[Flexo Flaw Fixing] Dirty Print](https://flexopedia.net/wp-content/uploads/2022/08/dirty_print-400x250.jpeg) 𝔰𝔯𝔠 Tooraj yousef

𝔰𝔯𝔠 Tooraj yousef[Flexo Flaw Fixing] Dirty Print

This article is part of the FLEXO FLAW FIXING series In the world of flexo printing, a clean and flawless print is not just an expectation, it is the standard...

![[Flexo Flaw Fixing] Smudging & Bleeding](https://flexopedia.net/wp-content/uploads/2022/07/065_Bleed_and_Smudge-jpeg-e1703152304722-400x250.webp) 𝔰𝔯𝔠 Max Stanworth

𝔰𝔯𝔠 Max Stanworth[Flexo Flaw Fixing] Smudging & Bleeding

This article is part of the FLEXO FLAW FIXING series If you are looking for information about bleeding and smudging in flexo printing, you have come to the...

![[Flexo Flaw Fixing] Horizontal Streaks](https://flexopedia.net/wp-content/uploads/2022/07/063_Transverse_Stripes-jpeg-e1703168980304-400x250.webp) 𝔰𝔯𝔠 Xue Chen

𝔰𝔯𝔠 Xue Chen[Flexo Flaw Fixing] Horizontal Streaks

This article is part of the FLEXO FLAW FIXING series A prevalent issue in flexo printing that often vexes printers is the appearance of transverse, horizontal...

[Flexo Flaw Fixing] Low Ink Adhesion

This article is part of the FLEXO FLAW FIXING series In the specialised field of printing, achieving perfect harmony between ink and substrate is paramount...

![[Flexo Flaw Fixing] Inconsistent Repeat Length](https://flexopedia.net/wp-content/uploads/2023/06/066_Repeat_Length-jpg-e1704202472468-400x250.webp) 𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFA[Flexo Flaw Fixing] Inconsistent Repeat Length

This article is part of the FLEXO FLAW FIXING series In the complex and intricate world of printing, achieving precision and quality is paramount. One of the...

![[Flexo Flaw Fixing] Vertical Streaks](https://flexopedia.net/wp-content/uploads/2022/07/062_Longitude_Stripes-jpeg-e1703168839289-400x250.webp) 𝔰𝔯𝔠 Xue Chen

𝔰𝔯𝔠 Xue Chen[Flexo Flaw Fixing] Vertical Streaks

This article is part of the FLEXO FLAW FIXING series Achieving flawless flexo prints is a delicate balance of art and science. A common defect that challenges...

![[Flexo Flaw Fixing] Moiré Effect](https://flexopedia.net/wp-content/uploads/2022/07/moire_effect-400x250.png) 𝔰𝔯𝔠 Esko

𝔰𝔯𝔠 Esko[Flexo Flaw Fixing] Moiré Effect

This article is part of the FLEXO FLAW FIXING series Moiré effect in flexo printing is an annoying phenomenon characterised by unwanted patterns created when...

[Flexo Flaw Fixing] Minor Defects

This article is part of the FLEXO FLAW FIXING series In the world of flexo printing, irregular specks can often be the bane of printers, resulting in unwanted...

𝔰𝔯𝔠 Anyflexo

𝔰𝔯𝔠 AnyflexoFlexo Plate Mounting Tapes Conversion

https://youtu.be/yFBk7v6YNO0 Plate Conversion at our Vendor facility - Innovaflexo GmbH How are Flexo Plate Mounting Tapes Converted to Custom Size...

[Flexo Flaw Fixing] Mechanical Damage to the Print Image

This article is part of the FLEXO FLAW FIXING series The problem of Mechanical damage to the print image in flexo printing Mechanical damage to the print...

![[Flexo Flaw Fixing] Screen Dot Inaccuracy](https://flexopedia.net/wp-content/uploads/2022/05/039_Deformed_Dots-400x250.png) 𝔰𝔯𝔠 Magica

𝔰𝔯𝔠 Magica[Flexo Flaw Fixing] Screen Dot Inaccuracy

This article is part of the FLEXO FLAW FIXING series Screen dot inaccuracies can stem from various factors. One prevalent cause is improper machine setup....

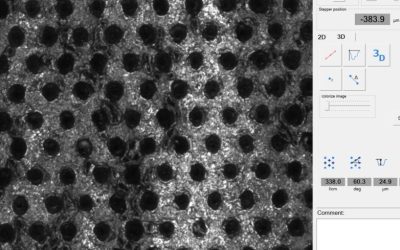

𝔰𝔯𝔠 Troika Systems

𝔰𝔯𝔠 Troika SystemsHow to Inspect Anilox Rollers – A Basic Guide Part 3

The article was prepared and submitted to us by Troika Systems Ltd. In the previous article we spoke about the advantages of having an Anilox Roller...

𝔰𝔯𝔠 Troika Systems

𝔰𝔯𝔠 Troika SystemsHow to Inspect Anilox Rollers – A Basic Guide Part 2

The article was prepared and submitted to us by Troika Systems Ltd. In the last article we talked about the how to start your anilox roller inspection. This...

How to Inspect Anilox Rollers – A Basic Guide Part 1

The article was prepared and submitted to us by Troika Systems Ltd. For many printers the anilox is a simple product to carry ink to their Flexo plate and it...

[Flexo Flaw Fixing] Defects in Large Format Printing

This article is part of the FLEXO FLAW FIXING series There are some challenges to working with flexo printing, and one of these is a significant area printing...

![[Flexo Flaw Fixing] Ink Buildup on Motif Edges](https://flexopedia.net/wp-content/uploads/2022/06/053_Ink_Build_Up-jpeg-e1703170141274-400x250.webp) 𝔰𝔯𝔠 Fkhan8681

𝔰𝔯𝔠 Fkhan8681[Flexo Flaw Fixing] Ink Buildup on Motif Edges

This article is part of the FLEXO FLAW FIXING series Have you ever wondered why you see ink buildup on the edges of motifs in a flexo printing job? If...

[Flexo Flaw Fixing] Too Weak Colour

This article is part of the FLEXO FLAW FIXING series Colour is critical in flexo printing. It defines the final product's quality and appeal in the...

![[Flexo Flaw Fixing] Misregistration](https://flexopedia.net/wp-content/uploads/2022/06/049_Misregistration_CMYK-400x250.png) 𝔰𝔯𝔠 Jyon

𝔰𝔯𝔠 Jyon[Flexo Flaw Fixing] Misregistration

This article is part of the FLEXO FLAW FIXING series In the world of flexo printing, misregistration can be a frustrating obstacle to the seamless creation of...

[Flexo Flaw Fixing] Pinholing

This article is part of the FLEXO FLAW FIXING series What Is The Pinhole Effect? Sometimes, the ink does not completely cover the print surface. Small holes...

[Flexo Flaw Fixing] Ghosting Effect

This article is part of the FLEXO FLAW FIXING series Ghosting effect in flexo printing appears as a faint, shadowy image that appears out of place. It betrays...

[Flexo Flaw Fixing] Halo Effect

This article is part of the FLEXO FLAW FIXING series What Is The Halo Effect? Flexographic printing is a pressure-sensitive method of printing. Pressure is a...

![[Flexo Flaw Fixing] Ink Mottling](https://flexopedia.net/wp-content/uploads/2022/06/Mottled_Print-400x250.png) 𝔰𝔯𝔠 No Chintz

𝔰𝔯𝔠 No Chintz[Flexo Flaw Fixing] Ink Mottling

This article is part of the FLEXO FLAW FIXING series In the sophisticated arena of flexo printing, achieving flawless print quality is paramount for those who...

[Flexo Flaw Fixing] Too Strong Colour

This article is part of the FLEXO FLAW FIXING series What is the Color Strength of a Flexo Print? The color strength of a flexo print measures how much...

[Flexo Flaw Fixing] Fill-In and Bridging

This article is part of the FLEXO FLAW FIXING series Flexo printing adds vibrancy to our daily encounters with packaging, but when fill-in or bridging defects...

Laser Imaging in Flexo Platemaking

This blog was written and submitted to us by Torben Wendland During laser imaging in flexo platemaking, the printing design is transferred from the file...

Main Exposure in Flexo Platemaking

This blog was written and submitted to us by Torben Wendland In this article, we move on to the next stage, main exposure, in flexo platemaking. Main Exposure...

![[Flexo Flaw Fixing] Screen Dot Deformation](https://flexopedia.net/wp-content/uploads/2022/05/039_Deformed_Dots-400x250.png) 𝔰𝔯𝔠 Magica

𝔰𝔯𝔠 Magica[Flexo Flaw Fixing] Screen Dot Deformation

This article is part of the FLEXO FLAW FIXING series In the complex world of flexo printing, producing crisp, clear images is paramount. But sometimes a...

![[Flexo Flaw Fixing] High Dot Gain](https://flexopedia.net/wp-content/uploads/2022/03/020_Dot_Gain_Illustration-400x250.png) 𝔰𝔯𝔠 Esko

𝔰𝔯𝔠 Esko[Flexo Flaw Fixing] High Dot Gain

This article is part of the FLEXO FLAW FIXING series In flexo printing, high dot gain not only compromises image clarity, but also affects overall print...

[Flexo Flaw Fixing] Blocking

This article is part of the FLEXO FLAW FIXING series In the sophisticated world of flexo printing, there are a myriad of challenges that can get in the way of...

𝔰𝔯𝔠 Troika Systems

𝔰𝔯𝔠 Troika SystemsCorrect Use of Laser Cleaning for Anilox Rollers

This study was conducted and the article was prepared and submitted to us by Troika Systems Ltd A study on effects of laser cleaning (because of...

𝔰𝔯𝔠 ECTran71

𝔰𝔯𝔠 ECTran71The Flexographic Printing Process and the Differences between the Printing Unit Variants

This blog was written by Sandra Kaiser from Flexo Consulting A wide range of materials can be printed using flexographic printing; technically speaking,...

Flexographic Plates Troubleshooting: Problems, Solutions and Causes – Part 3

This is a continuation to the series of flexo plates troubleshooting Part 1 and Part 2. Hyperlinks have been added here, in case you have not read the...

Flexographic Plates Troubleshooting: Problems, Causes and Solution – Part 2

This is a continuation to the series of article part 1 on flexo plates troubleshooting. If you have not read the first article to flexo plates...

Flexographic Plates Troubleshooting: Problems, Causes and Solutions – Part 1

It is important to have a good quality flexo Plate in order to get a high quality print. To achieve this, the technician should be familiar with enough...

Flexo Prepress Quality Control

The controlling of prepress phase in flexo printing is where the print quality wins or lose the battle. It's a critical series of steps that requires careful...

Back Exposure in Flexo Platemaking

This blog was written and submitted to us by Torben Wendland The back exposure of a flexo photopolymer printing plate is creating the base (or floor) of...

𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFAFlexo vs Offset Printing: A Comprehensive Comparison

Flexo vs offset printing are two of the most prevalent techniques for jobs demanding consistent quality and long printing runs in the printing industry, each...

𝔰𝔯𝔠 RawPixel

𝔰𝔯𝔠 RawPixelUnstacking the Benefits of Stack-Type Flexo Press

Flexo printing continues to be a cornerstone in the packaging and label printing industry. Within this sector, the stack-type flexo printing press stands out...

𝔰𝔯𝔠 IMC

𝔰𝔯𝔠 IMCKey Consumables in Flexo Printing

Flexo printing, known simply as flexo, has become an indispensable printing technique, favoured for its versatility and efficiency. As with any sophisticated...

The Pre Press Process

In the pre press process, after a design has been trapped, distorted to compensate for plate elongation, and electronically imposed (considering...

𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFAPrepress Checklist for Flexo Printing

Before embarking on a flexographic print job, several critical factors must undergo meticulous scrutiny to ensure precision and quality. These factors...

Flexo Platemaking of Photopolymer Plates

This blog was written and submitted to us by Torben Wendland In flexo platemaking, Photopolymer printing forms (different from direct engraved printing...

𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFAColour Management in Flexo Printing

Effectively managing colours in flexographic printing pose distinct challenges due to varied substrates, non-standard ink hues, and unique dot gain...

𝔰𝔯𝔠 Bearfotos

𝔰𝔯𝔠 BearfotosWhat are Flexo Cleaning Products ?

Here are the basic types of flexo cleaning products. It is essential for your business to regularly clean and maintain your flexography equipment. By keeping...

𝔰𝔯𝔠 Sandra Kaiser

𝔰𝔯𝔠 Sandra KaiserColour in Flexo Printing

This blog was written and submitted to us by Sandra Kaiser. Visit Flexo Consulting to know more. How is colour created and how can colour be...

𝔰𝔯𝔠 AGFA

𝔰𝔯𝔠 AGFAWhat is Halftone & Screening in Flexo?

Halftone and screening in flexo is a special printing technique. Let's understand it better. Throughout its history, flexography has been printing quality...

𝔰𝔯𝔠 Esko

𝔰𝔯𝔠 EskoDot Gain in Flexo Printing

Dot gain is a prevalent occurrence in flexo printing and all printing processes. As dots transition from film to plate, they typically increase in size during...

𝔰𝔯𝔠 AFGA

𝔰𝔯𝔠 AFGAFlexography Technology

Flexography or flexo printing is characterized as a relief process. The image areas on the compressible plate are raised above the surrounding non-image...

Wide Web flexo printing process

In recent years, flexography has grown at the fastest rate. Many flexographic printing sectors have contributed to this growth, including wide web flexible...

The Flexography Market

The use of flexography is growing in popularity in today’s printing markets, where short run, low-cost, and high-quality are crucial to success. The...

Printing Presses for Flexographic Printing

Two very different types of flexo printing machines are of utilisation in packaging printing. One is central impression (CI) presses, where usually 8-10...

𝔰𝔯𝔠 ImpressAB

𝔰𝔯𝔠 ImpressABInks and Additives in Flexo Printing

A highly versatile and efficient printing process used in a wide range of industries, flexographic printing benefits significantly from the use of advanced...

Flexography Artwork Prepress Guidelines For Flexible Packaging – Label and Corrugated Carton

Artwork prepress Guidelines for Designers in flexible packaging Here are some basic guidelines for artwork prepress. Typography: Know the Print Process...

Coatings and varnishes for printing inks

What are coatings and varnishes for printing inks in flexographic printing? Introduction In flexographic printing, coatings and varnishes for printing...

Gravure vs flexo cost comparison

To compare the cost of Gravure vs Flexo printing method, we must understand the process of each. HOW DOES FLEXO PRINTING WORK? Flexible printing, often called...

𝔰𝔯𝔠 PxHere

𝔰𝔯𝔠 PxHereIn-Line Flexo Press: Revolutionising Print Efficiency

Flexo printing has long been synonymous with versatility and adaptability, suiting a range of applications from packaging to labels. At its core, the in-line...

Central Impression Drum

What is central impression drum? Central impression drum is sometimes referred to as a drum press, common impression press, or CI press. The press itself...

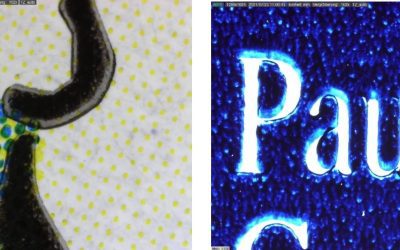

𝔰𝔯𝔠 Sandra Kaiser

𝔰𝔯𝔠 Sandra KaiserTypical Flexographic printing identification features

This blog was written and submitted to us by Sandra Kaiser. Visit Flexo Consulting to know more. As with other printing processes, there are typical...

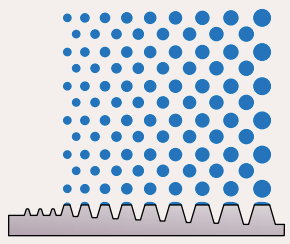

𝔰𝔯𝔠 DFTA

𝔰𝔯𝔠 DFTAFlexographic Printing Plates

Halftone dots of a flexographic printing plate in different diameters (source: DFTA) What are flexographic printing plates? Flexographic printing uses...

𝔰𝔯𝔠 APEX

𝔰𝔯𝔠 APEXAnilox Rollers and Anilox Sleeves

What are Anilox Rollers and Anilox Sleeves? Anilox rollers and anilox sleeves are used in short inking units such as flexographic printing, and sometimes also...

![[Flexo Flaw Fixing] Washboard Effect](https://flexopedia.net/wp-content/uploads/2022/02/image3-400x250.jpeg) 𝔰𝔯𝔠 Sandra Kaiser

𝔰𝔯𝔠 Sandra Kaiser[Flexo Flaw Fixing] Washboard Effect

This blog was written and submitted to us by Sandra Kaiser. Visit Flexo Consulting to know more. This article is part of the FLEXO FLAW FIXING...

Flexographic Printing – Pros & Cons

Why specifically is flexo printing so effective and economically interesting as a printing process? What are the advantages and disadvantages of flexographic...

𝔰𝔯𝔠 ECTran71

𝔰𝔯𝔠 ECTran71How Does A Flexo Inking Unit Work?

In the diverse world of printing, the question of how flexo presses transfer images onto substrates opens up a discussion on the pivotal role of the flexo...

Flexographic printing in the mirror of time

Things to know about the flexographic printing process Flexographic printing is one of many printing processes, but it is a particularly beautiful, versatile...

What is Flexographic Printing?

What is flexographic printing and why is it so predestined for pulp and packaging? Flexographic printing - the term itself already hints at it: Flexo printing...

How to Mount Post Print Flexo Plates | Anyflexo Tutorials

https://www.youtube.com/watch?v=dX7uVNKQIrI How to mount large flexo printing plates ? Welcome to Anyflexo Tutorials. In this video we explain how to mount...

𝔰𝔯𝔠 Anyflexo

𝔰𝔯𝔠 AnyflexoPrinting on very large designs with corrugated Board | Anyflexo Tutorials

In this tutorial, we'll show you a way how to print on very large designs with corrugated board! This technique is by the way a very good examples of the...

𝔰𝔯𝔠 IMC

𝔰𝔯𝔠 IMCHow to ensure a safe label press run by making the right choices?

No matter if you mount a few cylinders on your label press or up to 100 wide web sleeves a day. The mounting always has an impact on the print result. When...

𝔰𝔯𝔠 IMC

𝔰𝔯𝔠 IMCFlexo cushion backing foam: Special Nonwoven layer for corrugated printing

Flexo cushion backing foam helps in better handling of the printing plate in corrugated cardboard post print Ground-breaking for the still young company...

![[Flexo Flaw Fixing] Gear Marks](https://flexopedia.net/wp-content/uploads/2022/07/Dirty_Marks-400x250.webp)

![[Flexo Flaw Fixing] Ink Spitting](https://flexopedia.net/wp-content/uploads/2022/11/068_Dirty_Print-400x250.webp)

![[Flexo Flaw Fixing] Skip-Out Effect](https://flexopedia.net/wp-content/uploads/2022/07/070_Skip_Out-400x250.png)

![[Flexo Flaw Fixing] Feathering](https://flexopedia.net/wp-content/uploads/2022/07/069_Feathering-400x250.webp)

![[Flexo Flaw Fixing] Low Ink Adhesion](https://flexopedia.net/wp-content/uploads/2022/07/Adhesion_Tape_Test-400x250.png)

![[Flexo Flaw Fixing] Minor Defects](https://flexopedia.net/wp-content/uploads/2022/07/060_Minor_Defects-400x250.webp)

![[Flexo Flaw Fixing] Mechanical Damage to the Print Image](https://flexopedia.net/wp-content/uploads/2022/07/059_Mechanical_Damage-400x250.webp)

![[Flexo Flaw Fixing] Too Weak Colour](https://flexopedia.net/wp-content/uploads/2022/05/Colour_Strength-400x250.webp)

![[Flexo Flaw Fixing] Pinholing](https://flexopedia.net/wp-content/uploads/2022/06/048_Pinhole-400x250.png)

![[Flexo Flaw Fixing] Ghosting Effect](https://flexopedia.net/wp-content/uploads/2023/07/Screenshot-2023-07-27-at-15.38.51-400x205.png)

![[Flexo Flaw Fixing] Fill-In and Bridging](https://flexopedia.net/wp-content/uploads/2022/11/041_Dot_Bridging-e1704216170227-400x250.png)

![[Flexo Flaw Fixing] Blocking](https://flexopedia.net/wp-content/uploads/2022/05/038_Ink_Blocking-400x250.webp)